Measurement technology

Images

Measurement technology of the future

«Close to production, can be automated, measure as manufactured, universal: Efficient measurement applications»

Challenge: Industrial measurement technology is changing. The pressure for measurement close to production is becoming ubiquitous. Increasing productivity by shortening lead times and measurement cycles calls for new methods and possibilities. Who produces as designed and measures as manufactured not only has decisive advantages, but it is also increasingly becoming an absolute obligation. Increasing demands for safety in every respect combined with cost pressure are global trends.

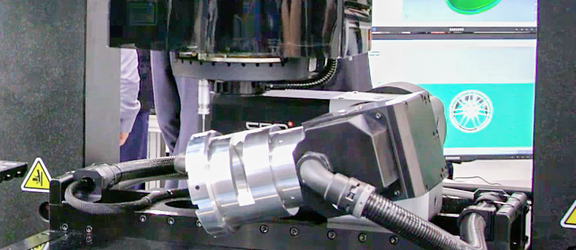

Investment consideration: It should be possible to measure workpieces as close to production as possible. Measurement should be automatic whenever possible and use the clamping means and devices commonly found on production machinery. Using one- or two-axis rotary tables from pL LEHMANN, two or more measurement applications are possible on the same machine: e.g., shaft measurement, coordinate measurement and roundness check in one. CNC rotary tables from pL LEHMANN that can be operated without compressed air, without hydraulics and with a high-level of repeat accuracy are ideal for this purpose.

Real-world expectation: Well-engineered technology must contribute to high availability and low maintenance. And finally, the user needs a variety of standardized clamping systems in a free market for optimal clamping of workpieces of any kind or use of handling systems and robots for semi-automatic or fully automatic operation. pL LEHMANN offers it all.